Ampaire's hybrid-electric vision expands air travel possibilities

CEO Kevin Noertker tells us why Ampaire wants to integrate their hybrid-electric propulsion technology into existing aircraft.

Summary

Ampaire believes that retrofitting small regional aircraft offers a cost-effective and practical solution for improving efficiency and reducing carbon emissions today.

By combining highly efficient fuel-burning engines with electric motors and battery packs, Ampaire's hybrid-electric planes offer greater power and range compared to all-electric aircraft.

Retrofitting existing planes allows quicker regulatory approvals and avoids the immense undertaking and costs associated with developing entirely new aircraft.

Ampaire says its aircraft require no charging infrastructure, opening up cost-effective and low carbon air connectivity to thousands of smaller communities.

The company has already achieved concrete milestones, including successful test flights and orders from leasing companies and airlines.

Ampaire’s elevator pitch

“Ampaire is a pioneer in sustainable aviation, focused on hybrid electric propulsion technology, as it integrates into planes,” says Ampaire CEO Kevin Noertker, when asked about the company’s mission.

Noertker talks about Ampaire “driving a more efficient and economical future for aviation.”

“Electrification is changing everything in this industry, and will ultimately touch everything that flies.”

A well-established name in the next-generation aviation sector, Ampaire specialises in retrofitting small regional aircraft with hybrid-electric technology. Their initial project involves upgrading the Cessna Grand Caravan, a nine-seat turboprop aircraft that has been in service since 1984 and holds certifications in over 100 countries.

An Ampaire whitepaper comprehensively explains how this "Eco-Caravan” will work.

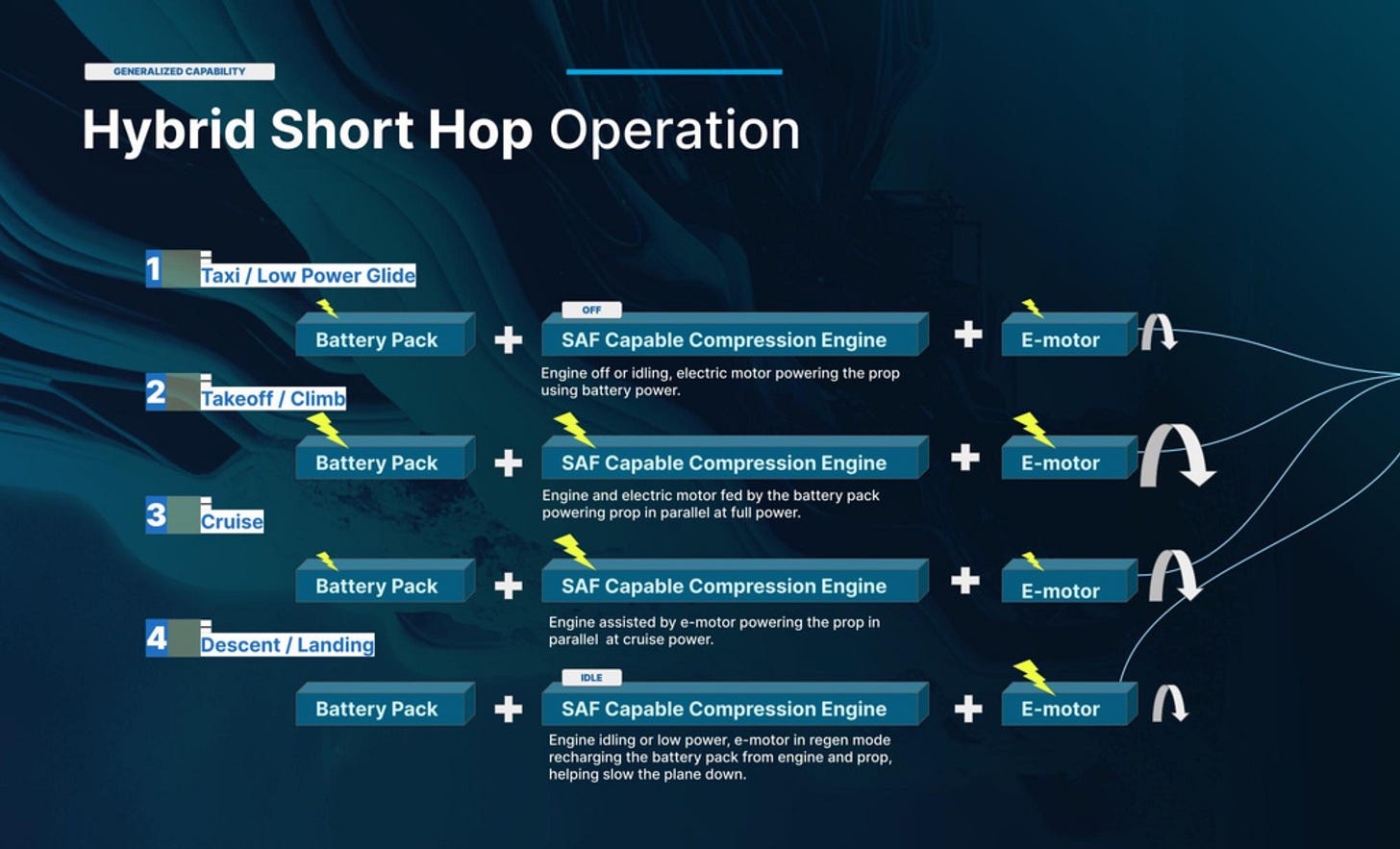

The design combines a highly efficient fuel-burning engine, an electric motor, and a battery pack. During take-off and climb, the battery supplies power to the electric motor, which, combined with the engine, delivers greater power than the original turbine engine. In cruise mode, the power distribution between the battery and turbine engine depends on the flight distance.

Ampaire says that this approach offers both significant operating cost savings as well as far lower carbon emissions compared to conventional aircraft equivalents. Even using current battery technology, Ampaire says it can save 70% on fuel on short routes, and 50% on longer routes.

Why hybrid-electric?

Noertker reveals that Ampaire chose the hybrid-electric approach for several reasons:

All-electric has limitations: Relying solely on battery power for the Caravan presented significant limitations. Previous attempts resulted in the cabin being filled with batteries, leaving little room for passengers. Noertker calls such a setup “a wonderful demonstration of technology”, but not a working and sellable product.

Hydrogen propulsion is not yet developed: When it comes to hydrogen, the other alternative propulsion system, Noertker believes that it still “has a lot of risks and challenges associated with it…which compound upon each other to decrease the level of believability of it as a near-term reality for aviation.”

Quicker and cheaper to certify: By focusing on hybrid-electric retrofits, Ampaire is investing in existing technology that possesses a certification path and does not require exorbitant costs or massive infrastructure upgrades.

In its whitepaper, Ampaire also highlights the approximately 10,000 airstrips in the US, many of which lack a power supply or chargers for aircraft.

By functioning independently of traditional infrastructure, Ampaire's configuration — similar to a Toyota Prius in the sky — opens up air travel to numerous communities that don’t have or lost their connections decades ago.

Noertker illustrates this by comparing his own situation, living in Los Angeles with easy access to a major international airport, to the reality faced by individuals in remote areas without such convenience.

He argues that it’s not a question of “can we put international airports into every county?” Instead, he believes Ampaire answers “can we provide connectivity to communities around the world at price points which are accessible?”

By reducing fuel consumption, Ampaire lowers operating costs for airlines, making it economically feasible to revive routes that were abandoned decades ago:

"Decreasing fuel burn suddenly decreases operating costs, enabling airlines to justify flying routes they may have last flown in the 1980s.”

Retrofit vs a clean sheet design

Ampaire's decision to retrofit existing regional aircraft rather than developing entirely new ones stems from Noertker's belief in the most efficient and effective solution.

“Developing a clean sheet plane is an immense undertaking,” Noertker says. He adds that it would involve putting a lot of focus on the aircraft design, which may not even be that novel compared to existing aircraft.

Instead, he believes that what counts is replacing the propulsion systems, and looking at how planes can be made less fossil fuel dependent — and, as a result, both cheaper to operate as well as less carbon-intensive.

“By focusing on retrofitting existing planes, we can get the propulsion systems right; we can get them through regulatory approvals more rapidly from supplemental type certificates, rather than new type certificates for planes.”

Noertker is also somewhat sceptical of new aircraft concepts in development, saying that they are based on technology that is still “make-believe”. It’s worth noting that Greg Davis, the CEO of all-electric aircraft maker Eviation, recently said that the batteries needed to power the company’s Alice aircraft don’t yet exist.

A cost-effective solution

Developing an entirely new aircraft often incurs costs of $1 billion or more. In contrast, Noertker says that Ampaire's retrofitting solution proves far more cost-effective than developing a new aircraft.

Ampaire already has some funding, including over $20 million awarded through NASA, the Department of Energy, the Department of Defense and international groups.

The big vision

Noertker says that Ampaire’s goal is to, first of all, retrofit all so-called ‘Part 23’ smaller aircraft.

When it comes to ‘Part 25’ aircraft, which encompasses most commercial passenger aircraft flying today, Noertker admits it is a “tough nut to crack”, especially with some of the larger aircraft in that category. He says they will require new technology, “such as power electronics and motors and things that are not there yet.”

However, Noertker points to some promising battery and semiconductor research and innovation work by organisations such as NASA and the US Department of Energy.

Our take

There are hundreds of next-generation aircraft companies in existence. Most have got no further than the design stage.

Ampaire is different in that it can show a number of concrete achievements. This includes flying the longest hybrid-electric mission ever — from California to Kansas in 2022; and aircraft orders from leasing company MONTE and Brazilian airline Azul among others. The company has also won an award from NASA for its hybrid power plant.

Their decision to work with what’s possible now in terms of technology means we should see Ampaire retrofitted aircraft flying sooner rather than later. The Eco-Caravan started test flights in November 2022. Ampaire expects it to be the first electrified regional aircraft to enter service as soon as 2024.