Cambridge startup HutanBio pioneers algae-based sustainable fuel without genetic modification

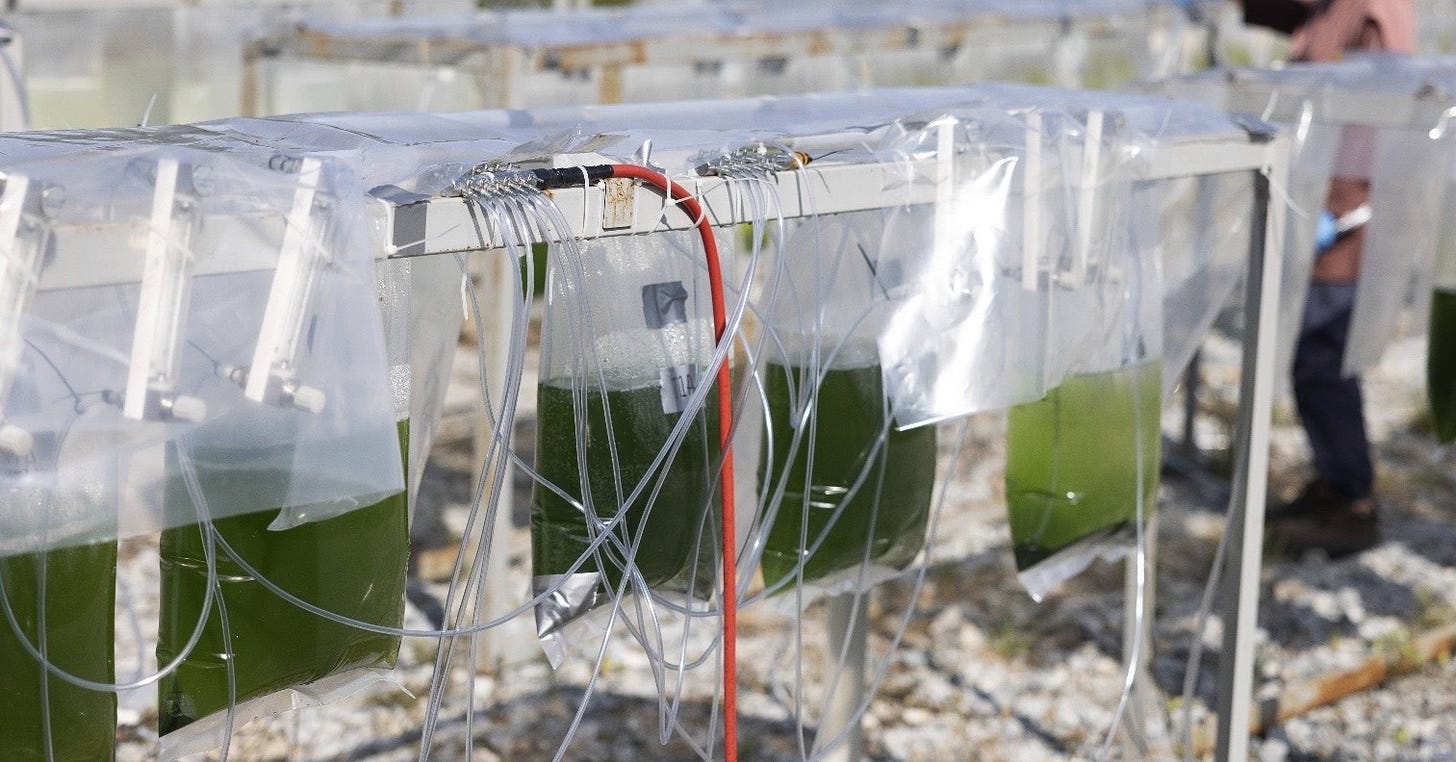

A flexible, scalable approach to algae farming that optimises land use and reduces costs.

A Cambridge (UK) startup called HutanBio says it has developed cost-competitive sustainable fuel from algae without requiring genetic modification or extensive arable land use, marking a significant departure from previous attempts at algae-based biofuels.

The technology builds on decades of research at the University of Cambridge and KAUST (King Abdullah University of Science and Technology), where the founding team developed groundbreaking advancements in high-density algae cultivation.

While companies like Viridos have spent years trying to turn genetically engineered algae into biofuels, HutanBio has taken a fundamentally different approach by identifying naturally robust strains that can thrive in desert coastal regions.

"A lot of people who play with algae take a lab-based strain, genetically modify it, and then they try and take it outside," explains Brittany Hook, Business Development Director at HutanBio.

Hook says that, in contrast, HutanBio has taken something that was “already hardy and productive" and brought it into the lab without trying to "force some genes into it."

Most significantly, HutanBio believes it has cracked the challenge of cost. "We've been currently benchmarking against marine, which is about twelve hundred to fifteen hundred dollars a tonne, and we are well within those parameters and still remaining profitable," says Hook.

For marine applications, their algal oil can be used directly without refining. "The molecule that our organism produces actually can be taken straight without refining or without chemical upgrading into marine fuel," Hook explains. Aviation fuel and road diesel would require co-processing chemical upgrading through a biorefinery.

Even so, Hook believes that HutanBio can still offer significant advantages over current sustainable aviation fuel (SAF), which typically costs two to seven times more than conventional jet fuel.

Scaling up through a modular cultivation architecture

Currently producing at somewhere between lab to pilot scale near Kuala Lumpur airport, HutanBio plans to expand from their current half-hectare site to a five-hectare facility. "We're hoping to have the site identified mid to late this year and live before the end of next year. And that would take us from litres of production to tonnes," Hook explains.

Hook has calculated that replacing half of current jet fuel usage with a 50% sustainable blend would require about 31,000 square kilometres of production facilities – "about one and a half times the size of Wales."

While this sounds substantial, it could be achieved through approximately 620 facilities of 50 square kilometres each, spread across multiple continents.

Their modular engineering approach makes this more achievable. According to Clean Growth Fund Investment Partner Jonathan Tudor, the company has developed a modular cultivation architecture designed for high-density algae growth, using compact, vertically integrated modules that optimise land use while reducing operational overhead.

"It's like Ikea... we don't have to dig a pit and line it with concrete and everything like that. It's quite easy to piece together. It's very modular," Hook explains. You can "plan for a massively scaled site, set up your downstream processing... and then add just a piece of the actual platform. And then you can be readily producing and selling oil at a smaller scale while you continue to add blocks."

Crucially, HutanBio's technology is designed to use land that has no other productive use. "One of the kind of core tenets we work from is that we don't think that we should starve people just to feel less guilty about flying," Hook emphasises. "Our algae is by design, high heat, high sun tolerance, high salinity tolerance."

The company is targeting coastal desert regions between 20 and 40 degrees latitude, areas that Hook describes as not useful for anything meaningful that supports human life. Hook says potential locations include the Middle East, sub-Saharan Africa, Morocco, and North Western Australia.

Carbon benefits

Beyond the production advantages, HutanBio's strain offers impressive carbon capture capabilities, with about 300 photosynthetic layers, compared to six to eight in previous strains.

"Our organism has got about 300 photosynthetic layers... And the analogy I like to make is it gets a tan, and it keeps working rather than getting a sunburn and wilting," Hook explains.

According to Tudor, for every tonne of biomass produced, approximately two tonnes of CO2 are captured, making the process inherently carbon-negative. The technology is robust enough to work alongside both point-source carbon capture and direct air capture.

While biofuel production is the primary focus, HutanBio's process generates additional value through its biomass byproduct. Tudor notes that algae biomass offers a sustainable, protein-rich alternative to conventional animal feeds such as soy, creating a diversified revenue stream while helping to alleviate pressures on resource-intensive agricultural systems.

Having secured £3 million in seed funding from Clean Growth Fund and UK Innovation & Science Seed Fund (UKI2S), HutanBio is now actively pursuing Series A investment.

The company recently strengthened its leadership team with the appointment of Dr Peter Collins as Chair, who brings significant experience in scaling technology-differentiated engineering businesses.

The road ahead

While other companies continue to work on genetic engineering approaches that could take years to perfect, HutanBio believes its solution is nearly ready for deployment.

"Our organism is ready to go. Our engineering is about eighty-five, ninety per cent there," Hook says, though she adds that they would want to run a proof-of-concept site for about six months "to learn what we don't know today about how it operates at scale."

Drawing on extensive global cultivation trials and research, HutanBio's technology could be particularly timely given recent regulatory developments, including the EU and UK SAF mandates and the International Maritime Organisation's mandate on reducing shipping emissions by 40 per cent by 2030.

However, Hook emphasises that HutanBio welcomes other producers and solutions, as it will take various players to reach aviation decarbonisation.

"The human race as a whole, we love the silver bullet solution," Hook concludes. "We want one solution to all of these problems, but we're going to have to get comfortable with some ambiguity and a bit of a mixture going forward."

For January 2025, we’re pleased to feature 4AIR as our exclusive Sponsor of the Month. 4AIR is leading the way with the industry’s first framework to address aviation’s climate impact – offering clear, verifiable pathways to reduce and counteract emissions. Discover their services, including compliance monitoring and The Assure SAF Registry, to advance your sustainability efforts.