Why Carbyon is betting on modular manufacturing to scale cheap carbon capture

Instead of building massive CO2-sucking facilities, Carbyon is betting on speed, modularity, and a radical cost target: €100 per tonne.

While major companies in the direct air capture (DAC) industry race to build ever-larger facilities, chasing economies of scale, a Dutch startup is taking the opposite approach.

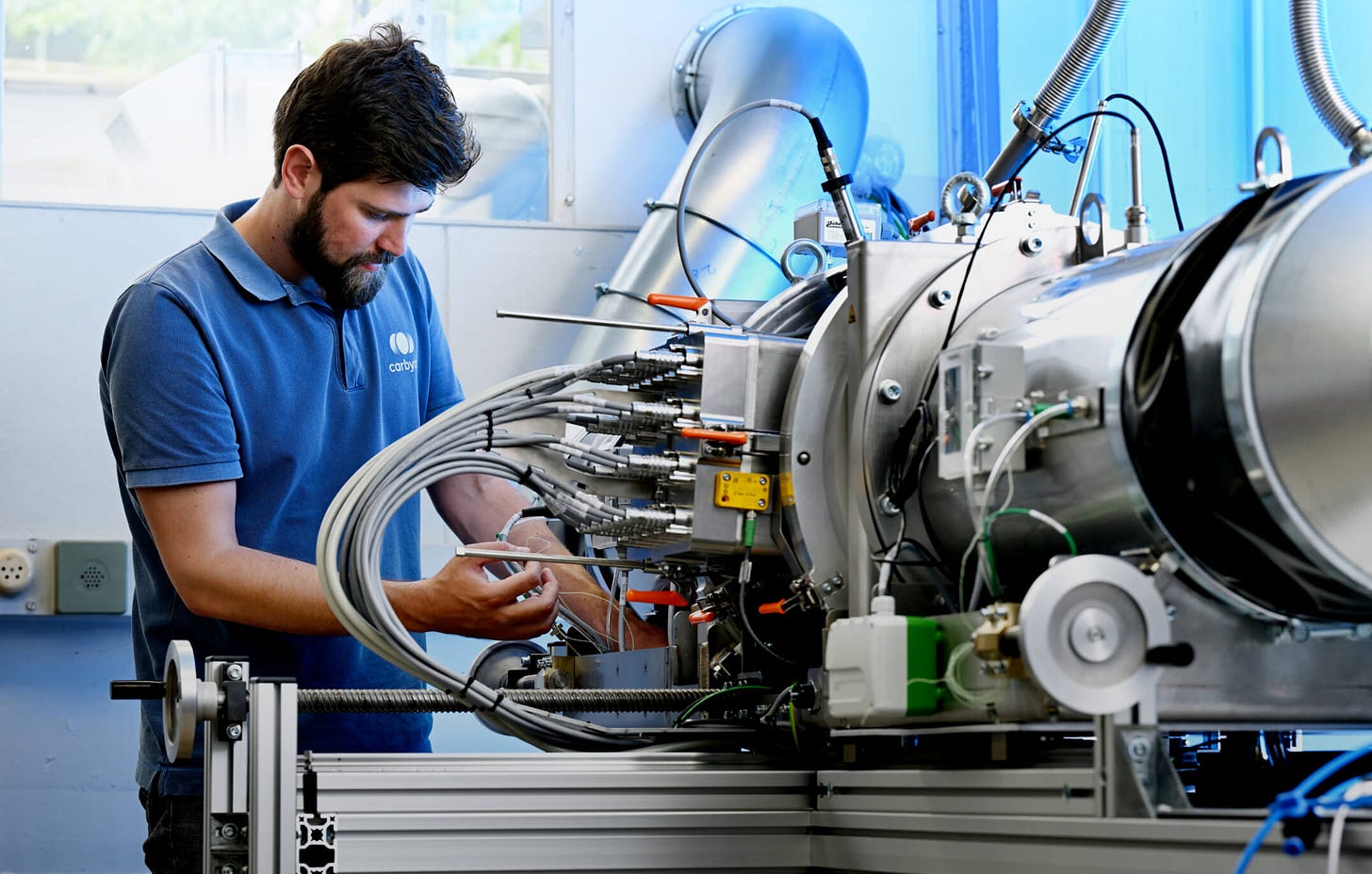

Eindhoven-based Carbyon's machines are deliberately small, deliberately modular, and deliberately fast. They complete CO2 capture cycles in 130 seconds, compared to hours for some competitors in this space.

It's a bet that speed and flexibility will matter more than size when aviation desperately needs carbon sources for sustainable fuels. The company aims to provide the necessary quantities at a competitive cost.

"Our mission is to capture billions of tonnes of CO2 from the air," says Tessel Jarigsma, Carbyon's COO, describing their ambition to scale through manufacturing rather than facility size.

Founded in 2019 as a spin-off from the Netherlands research institute TNO, Carbyon has developed what it calls "fast swing" technology. The approach uses surface-based sorbents with an extremely high surface area: 3,000 square meters per gram of material, enabling rapid CO2 absorption and release cycles.

Many traditional DAC systems operate in batch cycles lasting several hours. Carbyon's technology reaches 90% saturation in just minutes, enabling continuous operation. Each small unit measures 60cm by 12cm — "the size of your upper leg," as Jarigsma describes it — and can capture 500 kilograms of CO2 annually.

With plans to open its first pilot facility in Eindhoven in September, the company targets costs under €100 per tonne of CO2, significantly lower than current industry averages of €500+ per tonne.

A technology provider's business model

Unlike vertically integrated competitors such as Climeworks, Carbyon positions itself as a technology supplier rather than a project operator. "We are technology providers," Jarigsma emphasises, comparing their role to that of established industrial equipment companies like Topsoe or Siemens Energy.

This model puts the economics partially in the hands of its customers. "We need customers that can get [electricity] for 2 cents. And then, of course, it's 50 euros per ton," Jarigsma explains, illustrating how ultra-cheap electricity could drive down operating costs for buyers.

"I'm talking to a hydropower company in India. They just basically get it for free," she notes, giving an example of the kind of customer that could achieve these low costs.

The modular design enables this approach. "The beauty of DAC [is] you can do everywhere," Jarigsma notes. "There's no need to transport your CO2. You just put your DAC machine wherever you need it."

This means e-fuels companies serving the aviation and maritime sector and needing a cheap source of CO2 could put Carbyon’s machines where renewable energy is plentiful and affordable. Carbyon’s modular structure means that you can start small and add additional units as needed.

Alternatively, these units could be deployed near airports without requiring massive dedicated facilities.

The great DAC debate

Direct air capture remains one of the most contentious topics in climate technology. Critics point to three major pitfalls:

It enables continued fossil fuel use by providing a technological "out."

The costs will never reach commercially viable levels.

The massive energy requirements could be better deployed elsewhere.

In our conversation, Jarigsma tackled each criticism. On the moral hazard argument, she points out that atmospheric CO2 levels require active removal regardless of future emissions policies."Even if the fossil industry would immediately stop, we need to clean up the air to reverse climate change."

The cost criticism draws a historical analogy: "Every new technology will have a cost down curve. Whether it's the first plane that ever flew, or solar panels, or hydrogen, or whatever. Cost down only happens through adoption."

Finally, Jarigsma framed the whole debate in terms of waste management.

"We have been putting waste into the air, which was intangible, since 1950 or 1960," she continues. Like any waste, there is a price. And actually, the CO2 that we get is going to be valuable.” It can be used in a whole range of products, for example, e-fuels for aviation and maritime.

As a result, Jarigsma says that "CO2 has become an ugly thing because it created climate change. But CO2 is actually a very, very valuable molecule... if we treat it the right way."

On energy usage, Jarigsma acknowledges the legitimate concerns while questioning priorities: "It's very easy to criticise something that is sort of intangible, when we're using a lot of electricity to be in our data centres. All of that stuff is using so much more electricity."

Industry validation

Carbyon has secured funding from investors including Siemens Financial Services, Lowercarbon Capital, Omnes Capital, Bouygues, ISAI Build Venture and Global Cleantech Capital. In July 2025, it also became the first DAC company to receive a Dutch government DEI+ subsidy.

The company plans to deploy its first outdoor demonstration unit at High Tech Campus Eindhoven in September 2025, followed by commercial deployment to customers, including pilot partners, for field testing.

By 2030, Carbyon aims to be among the top five DAC companies globally, producing 30,000-50,000 machines annually. Whether this modular manufacturing approach can compete with mega-facility strategies will largely determine the industry's development path.

For aviation, technologies like Carbyon's represent one pathway to more cost-competitive, sustainable synthetic fuels, if they can deliver on their cost and scale promises.