Welcome to Season 2 of Sustainability in the Air, the world’s first podcast dedicated to sustainable aviation. Through in depth conversations with top aviation leaders, we break through the clutter and provide a clear roadmap for a net-zero future.

In this episode of our ‘Sustainability in the Air’ podcast, Dr. Mark Hiller, CEO at RECARO Aircraft Seating and Recaro Holding, speaks with SimpliFlying CEO, Shashank Nigam.

RECARO is the world’s leading aircraft seat manufacturer, based in Hamburg, Germany. Dr. Hiller dives deep in this conversation on the measures RECARO is taking to make flying greener today – from lighter seats that save 1000 tonnes of CO2 annually to eLeather.

You can listen and subscribe to our podcast below or read our deep-dive into the episode.

If you’re rushed for time, you can also directly jump to your topic of interest by referring to these time-stamps:

Aviation pre-pandemic and post-pandemic: Recaro’s perspective (2:28)

What has changed for the industry post-pandemic (4:19)

How to tell if it’s a Recaro seat when onboard (6:02)

Lifecycle assessment of onboard seats (6:58)

Nano-coating: increasing appealing appearance and durability (12:20)

Saving airlines 1000 tonnes of C02 emissions annually (14:44)

How thin can airline seats go if travellers still want to fly in comfort? (17:20)

Upcycling: giving airlines their aircraft seat materials back to create merchandise (23:28)

What Recaro is doing to reduce their carbon footprint (28:48)

Dr. Mark Hiller’s advice to CEOs on sustainability (33:45)

What airlines are doing wrong when it comes to sustainability (35:08)

Aircraft Seating: Impacts from Covid

2019 was a record year for RECARO – they clocked $700 million a year in revenues. Scroll forward to 2020 and 2021 and a tremendous downturn set in. The company lost more than 65% of revenues.

At this point, Dr Hiller and his team began exploring how travel would change. They soon realised that increasing efficiency and lowering the overall weight on the aircraft would be a major trend to focus on.

Full Circle: In the region, for the region

RECARO is the market-leader in Economy class aircraft seats. Their marketshare on a Boeing 787 or Airbus A350 is between 50-60%. There is a high probability that most passengers onboard one of these aircraft types will experience what flying on a RECARO seat is like, probably the lie-flat Business Class seats as well.

Dr. Hiller shares that developing a locally-sourced strategy is embedded in the business model as that is one of the most important ways of building greener seats. Purchasing local products from local suppliers is more sustainable and it supports communities around the world.

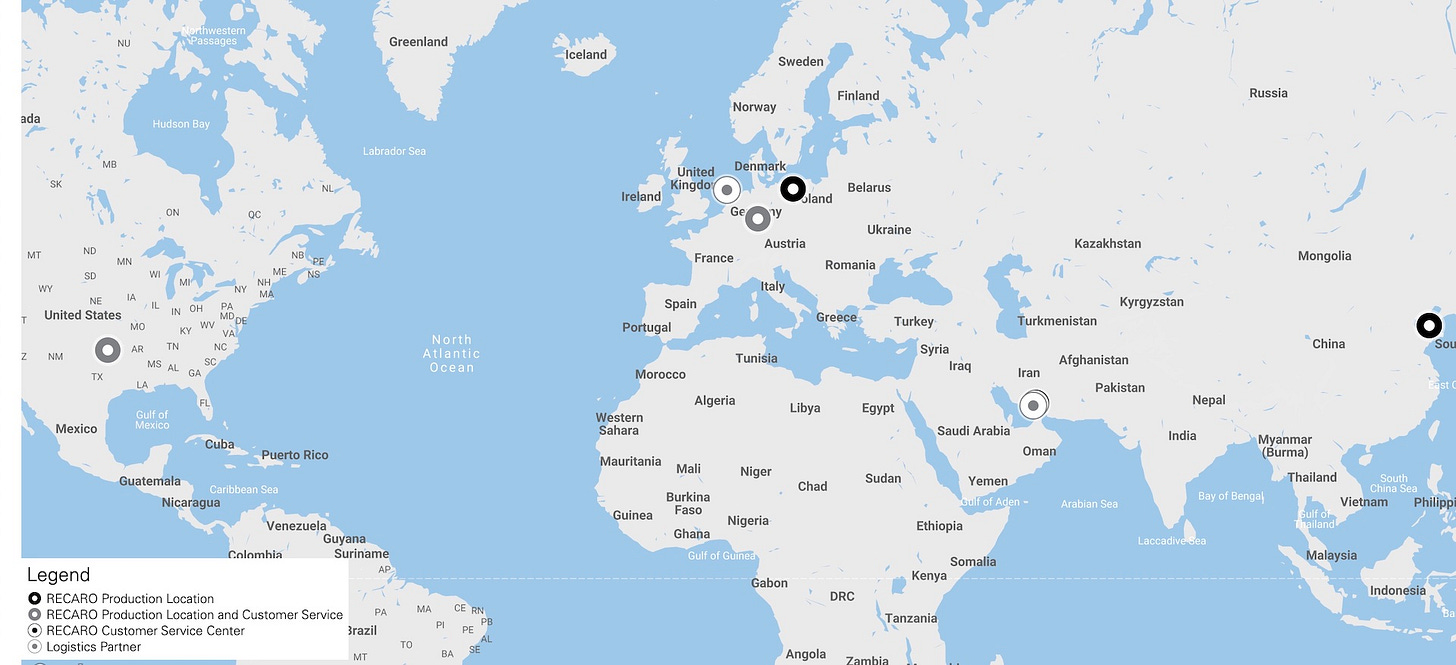

The company’s global operations are strategically placed close to their customers: A German and U.S. manufacturing plant; facilities in Poland, China, and South Africa, and servicing centers throughout the world.

Location, according to Dr. Hiller, matters because there is no point in focusing on a lightweight seat if it needs to fly across the world to the airline and the service center is tens of thousands of miles away, emitting thousands of CO2 emissions. That is why if the customer is U.S. based, all of their production and servicing is out of Fort Worth, Texas; in the Middle East, out of Abu Dhabi and Dubai; for Europe out of Stuttgart and Swiebodzin; Qingdao, China for Asia etc.

eLeather could be the future

RECARO also conducted a detailed lifecycle analysis to delve deep into the various factors involved in an airline’s aircraft seat requirements, specifically as it pertains to sustainability.

This included the usage phase; usage patterns; product usage duration; and the materials. A deep-dive into these elements formed the backbone of the research and development aspect to reach the lightweight seats and material.

An example of this is the development of eLeather seat material, a fusion of a large number of small scrap pieces of real leather pieces glued together to form one large homogenous material. This makes it much lighter yet stronger and it reuses old materials.

Cultivating Consciousness all the way through

Dr Hiller is keen to emphasise that 99% of a seat’s environmental impact is generated during usage. RECARO intends to be partners in extending the life of the aircraft seat. Prolonging the “in-use” durability of the aircraft seats and preserving the longevity reduces the carbon footprint of the seat, thus in turn minimizing environmental impact. They would rather see airlines upgrading their existing products as opposed to disposing of them and starting anew.

The overarching objective is counter-intuitive; instead of wishing to sell more seats, Dr. Hiller’s purpose is to build a life-long product, which is long-lasting and requires minimal upkeep.

Eco-comfort design exceeds expectations

Lightweight design is one of RECARO’s core competencies. On being asked about how his team builds super-thin seats while balancing comfort, Dr Hiller outlines the evolution of aircraft seats.

A decade ago, the seat back was a metal frame in the back, which has since been changed to be an aluminum back-rest laid with carbon fibre overlay, then covered with netting and foam and then dressed. This innovation resulted in reducing the weight by half, and increased comfort.

Our Take

Regardless of the nature of the business in aviation – airline, supplier, manufacturer – the recurring theme of sustainability strategies is impact. RECARO, as discussed in the podcast, are making seats with features such as removable trays and eLeather to minimise waste and reduce the carbon footprint. Going forward they’re aiming to keep only the features that will be in-use by the passenger. The removable trays concept, for example, is an excellent demonstration of this philosophy. Instead of automatically building trays into every seat, the tray will be provided ‘on demand’.

Speaking of waste, upcycling is an excellent strategy. There are many reasons to repurpose an aircraft product that was already in use – whether it is for nostalgia or various second lives.

Additionally, RECARO is setting a stellar example by incorporating sustainable practices into their corporate strategy as well. Dr. Hiller says the company uses renewable electricity at all of their sites; has upgraded their manufacturing footprint to paperless production; and is investing in new equipment to reduce their impact while eliminating the need for seats to be shipped around the world.

Dr. Hiller’s ends with a piece of sage advice that he received from his grandfather: “There is nothing that cannot be improved.”

Our Sustainability in the Air podcast is powered by SimpliFlying which has been helping build trust in travel for over a decade.

This season of the podcast is brought to you by CarbonClick, leaders in managing carbon offsetting programs for top global airlines.