Welcome to Season 3 of Sustainability in the Air, the world’s first podcast dedicated to sustainable aviation. Through in-depth conversations with top aviation leaders, we break through the clutter and provide a clear roadmap for a net-zero future.

Did you know that AIR COMPANY is turning thin air into sustainable aviation fuel, vodka, perfume, sanitiser, and more?

In this episode of our ‘Sustainability in the Air’ podcast, Gregory Constantine, Co-Founder and CEO of AIR COMPANY, joins SimpliFlying CEO Shashank Nigam to discuss his company’s groundbreaking vision for a sustainable future.

Tune in to the full episode below, or read our detailed breakdown. Pressed for time? Jump to the segments that interest you most using these timestamps:

Air Capture 101, how AIR COMPANY does it (3:08)

Addressing the supply challenge of SAF (7:12)

AIRMADE™ spirits and perfume: At an airport near you soon (13:00)

Price for CO2-based SAF (16:45)

Rocket fuel for NASA (17:55)

Challenges of a startup (19:40)

Airlines that are doing a good job towards getting to a net-zero target (20:54)

“Everything that we create, we create out of thin air”

The story begins a decade ago when Gregory Constantine ventured from Sydney to New York, where he worked for Diageo, one of the largest beverage companies in the world. Around 2017, he met Dr. Stafford Sheehan, and the two realised they shared a common goal: to make the world a better place. Following countless hours of iteration and innovation, they launched AIR COMPANY in 2019.

Not more than a year later, AIR COMPANY was recognised by TIME as one of the 100 Best Inventions of 2020 for distilling spirits from nothing more than water and carbon dioxide through a process that transforms CO2 into ethyl alcohol.

The sky is (literally) the limit

At AIR COMPANY, innovation begins with sourcing two key ingredients, carbon dioxide and hydrogen:

The CO2 can be captured from virtually any source, offering flexibility in how and where it's obtained.

Hydrogen is produced locally at their Brooklyn facilities, which is powered by renewable energy from a mix of solar and wind.

When carbon dioxide and hydrogen are combined in their reactors, the reaction produces a mixture of alcohols, paraffins, aromatics, and water, which forms the base of their products – most notably their sustainable aviation fuel (SAF).

This process is powered by AIR COMPANY’s proprietary AIRMADE™ technology, which mimics the natural process of photosynthesis, transforming CO2 into impurity-free alcohols with just three essential inputs: air (carbon dioxide), water, and sun (renewable energy).

Scaling for impact

AIR COMPANY’s business plan is driven by a key question: “How can we leverage our early-stage technology – when volumes are low and costs are high – to create a pathway into large-scale industries like aviation, where the outputs needed are massive and the cost needs to be very very low?”

According to Gregory, the company’s primary goal was always to “create the technology and make it work, first and foremost.” While that remained the focus, AIR COMPANY found revenue streams along the pathway to that scale thanks to its consumer products like vodka and fragrances.

Starting with the launch of a carbon-negative vodka, AIR Vodka, the company has since expanded its portfolio to include carbon-converted AIR Hand Sanitiser and AIR Eau de Parfum, among other consumer innovations in the pipeline.

However, AIR COMPANY has been able to take things further and has created a single-step 100% drop-in sustainable aviation fuel made from carbon dioxide.

A breakthrough in SAF production

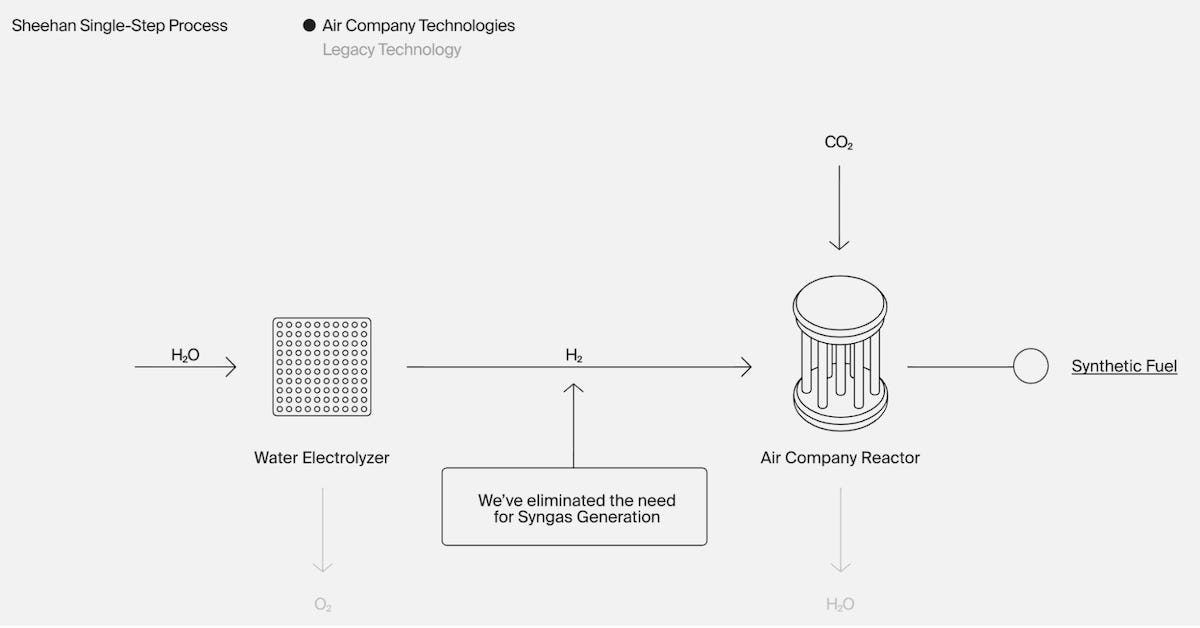

The traditional method for making synthetic fuel, known as the Fischer-Tropsch process, was developed in 1925 and relies on natural gas. It involves a series of steps where carbon monoxide and hydrogen in syngas (a mixture of both) are converted into hydrocarbons to produce fuel.

AIR COMPANY has revolutionised this with a patented single-step process that directly produces fuel-grade paraffins. What’s more, their fuel doesn’t require any blending, making it a highly efficient and cost-effective solution for CO2-based aviation fuels.

The roster

This innovation hasn’t gone unnoticed. JetBlue, Boom Supersonic, Virgin Atlantic, and the US Air Force are among AIR COMPANY’s clients. The company is also working with NASA to develop rocket fuel from captured CO2 and recently won an additional grant with them to continue its research and development of kerosene-based rocket fuel.

“The ability to innovate for space and how that can translate on Earth, NASA allows us to work on technology innovation without cost in mind; unlike the private commercial sector where cost is everything. When you have the ability to work on things without necessarily factoring in cost in mind, it really stirs innovation”, says Gregory.

With a growing list of clients, AIR COMPANY is expanding beyond the US and plans to build SAF production facilities in Asia and Europe.

Looking ahead

With 27 years to reach the industry’s net zero targets, Gregory remains optimistic about the future, convinced that aviation is on the right track and that the industry needs more companies working on SAF.

“What we’re seeing from an airline perspective in the US and Europe, is because of legislative changes, it’s helping drive consumer sentiment for wanting airlines to go green. But we need more of it.”

When asked about the competition, he believes that there isn’t enough of it. From his perspective, the fact that only a few companies have been able to fly test flights on SAF is a problem. He believes that collaboration is what is needed in order for it to be successful and produced at scale.

Our take

Though the aviation industry is working to rapidly increase the amount of SAF available, e-fuels developed by AIR COMPANY and a number of other industry players may end up being a better long-term bet than biofuels. That’s because there are a number of questions around biofuels, especially when it comes to land use and feedstock supplies.

By comparison, AIR COMPANY uses an infinite resource, CO2, and is betting that renewable energy will scale up to allow it to produce SAF at volume and at a competitive price. Obviously, simplifying the way SAF is made, which the company claims to have done, could also prove crucial in that regard.

However, in the aviation industry, momentum also counts for a lot and here AIR COMPANY has already received important votes of confidence from NASA, the US Air Force, Virgin Atlantic and JetBlue, just to name a few. As a result, it’s realistic to imagine that AIR COMPANY will only grow from here, and that its e-fuel will power aircraft in decades to come.

In summary, climate change and the aviation industry’s path to net zero by 2050 is dependent on new solutions to decarbonise air travel. The aviation industry is a leading contributor to excess CO2 in our atmosphere, and AIR COMPANY shares how they are playing their part in doing something about it.

AIR COMPANY is part of a larger revolution in sustainable aviation. See who else is making strides in SAF – download our free report on North American producers here.

Our Sustainability in the Air podcast is powered by SimpliFlying which has been helping build trust in travel for over a decade.

This season of the podcast is brought to you by Cirium and CarbonClick. As a sustainability partner, Cirium helps the aviation industry gain a much clearer view of carbon emissions and develop methods to reduce them, enabling on the industry promise to fly sustainably. CarbonClick is the industry leader in managing transparent carbon offsetting programs for individuals and top global airlines.