How SiriNor's electric jet engines could power the A320 of the future

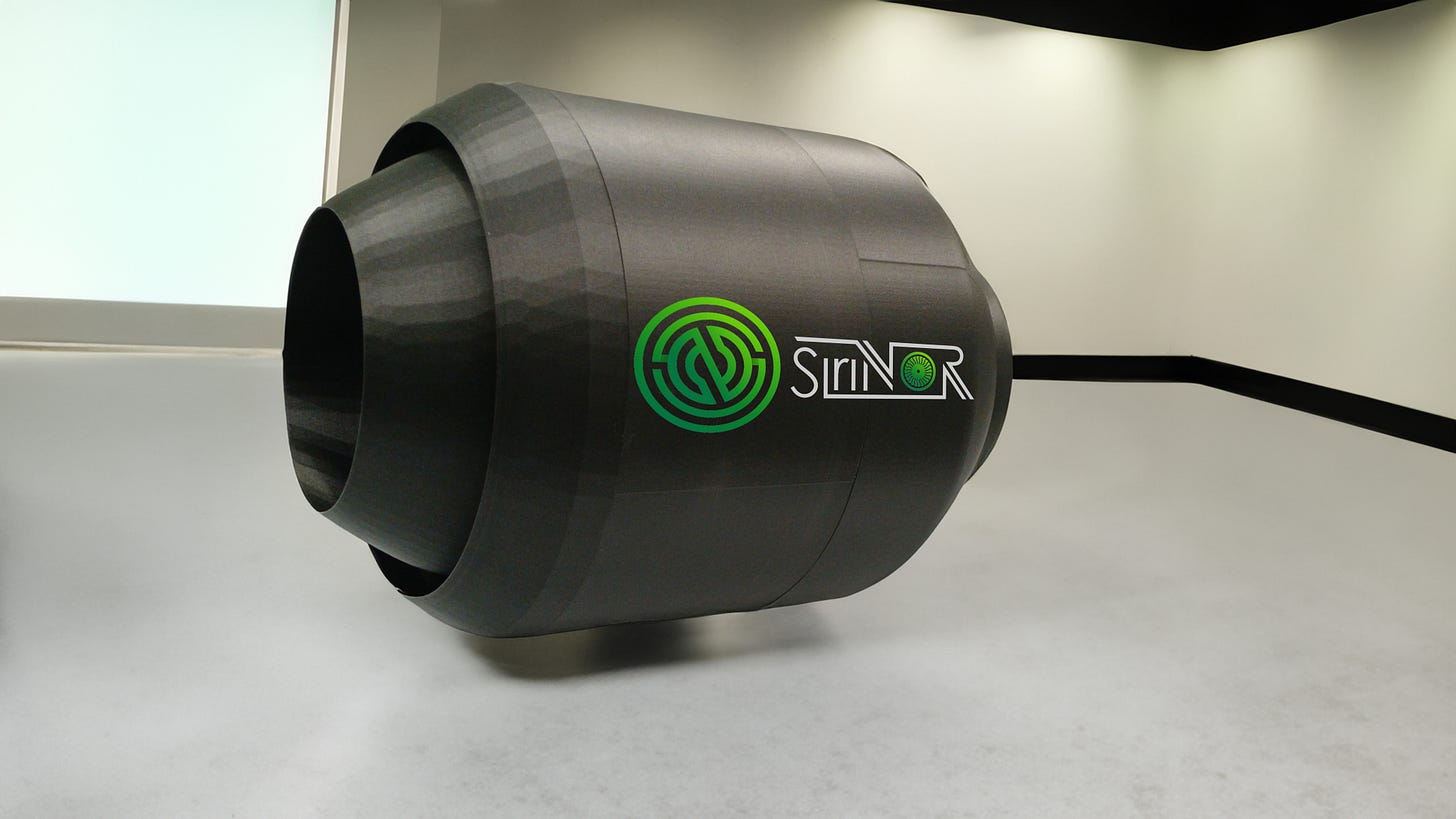

A Norwegian startup is reimagining electric jet engines with a focus on efficiency and a staged market entry strategy.

In a nutshell

Norwegian startup SiriNor combines innovative propulsion technology with a pragmatic, staged approach to market entry. The company believes that its tip-driven electric engine architecture could help bridge one of aerospace's most persistent challenges: achieving zero-emission flight at a commercial scale.

Tip-driven innovation

At the heart of SiriNor's innovation is a reimagining of electric propulsion. Instead of having one big motor in the centre (the hub) pushing the fan blades around, they put several smaller motors around the outer edge of the fan that use compressed air to spin it.

This architectural choice draws on basic mechanical principles, as CEO Ivar Aune explains through the following analogy:

"Think of the position of handles on doors. There's a reason why they are located where they are and not near the door hinges. It's to make doors easy to open and close. So why would you rotate a fan at its hub?"

SiriNor says that this decision leads to substantial technical advantages. By eliminating combustion, operating temperatures drop from 1600°C to 400°C, enabling the use of standard alloys and simplifying manufacturing processes. The company's testing indicates 20-30% energy savings compared to hub-driven alternatives while maintaining conventional jet engine dimensions.

Crucially, SiriNor has adopted a power-agnostic approach that acknowledges the uncertainty in aviation's energy transition – the engine could be powered either by batteries or hydrogen fuel cells.

"We are developing an electric jet engine, and what you use as your power source is up to whoever is operating the craft," says Aune. "But for now, liquid hydrogen and fuel cells will provide the longest range."

Their feasibility studies demonstrate that current-generation fuel cells, supplemented by batteries for peak loads during takeoff, could enable flights up to 4,000 kilometres with a 19-seat aircraft.

Incremental development vision

SiriNor's development strategy is deliberately incremental, recognising the technological and infrastructural advancements required to fully realise its vision.

Starting with 30cm diameter engines for UAVs and ground-effect vehicles, they plan to progress to 1-meter variants for larger UAVs and ground-effect vehicles in the near term. By the end of the decade, they intend to reach a point where they can power smaller commercial aircraft.

Their ultimate goal is to target commercial aviation with 2-meter engines capable of producing 90 kN of thrust – sufficient for aircraft in the Airbus A320 or Boeing 737 class.

They acknowledge that this particular milestone will likely require further technological advancements, particularly in fuel cells and batteries, and estimate a timeframe of the mid-2030s for achieving this.

This staged approach extends to their funding and manufacturing strategy. "We do not intend to build our own factory," Aune states. "We will utilise available capacity wherever that is. As a startup, we can pivot to wherever the market is, wherever the funding is, and wherever these things can be fabricated."

Funding and future

As a result, the funding ask is relatively modest compared to similar ventures.

The company estimates less than $10 million for UAV market entry capital requirements, scaling to approximately $30 million for ground effect vehicles and $70-80 million for aviation applications.

With the ability to license its IP and technology, SiriNor’s manufacturing model envisions global production networks. This comes as much of the team is based in India. "In India, we are talking with 3 or 4 manufacturers who not only manufacture additive 3D printing but also conventional manufacturing with aviation-grade machines," notes co-founder Abhijeet Inamda.

The immediate focus is securing €2 million to support 12-18 months of development, including TRL-6 testing of their 30cm prototype. This next phase will be crucial in validating both their technical innovations and manufacturing strategy.

However, SiriNor's leadership is realistic about the challenges ahead.

Aune admits that the major airframe manufacturers are currently defaulting to SAF because it offers the path of least resistance. As a result, the aviation industry's inherent conservatism and the complex interdependencies between aircraft design, propulsion systems, and energy infrastructure all affect the pace of transformation.

"Everything is relying on everything else," Aune reflects. "Why would Airbus design a large aircraft for electric propulsion if the electric jet engine isn't there? We are far too early, but as with all disruptive technologies, you must start early to be ready when the market is ready."

Our take

SiriNor's innovative approach to electric propulsion and its strategic focus on incremental development and collaborative manufacturing positions it as a potential player in the race to decarbonise aviation.

However, the company's success hinges on proving its technology and navigating the aviation industry's complex and evolving landscape. Whether SiriNor's vision will translate into widespread adoption depends on several factors, including the pace of battery and fuel cell development, regulatory frameworks, and the willingness of established aerospace giants to embrace new paradigms and thinking.

Given all these uncertainties and challenges inherent in disrupting the aviation industry, SiriNor's flexible approach with streamlined funding and manufacturing goals makes strategic sense.